Rib lath

Flat rib lath

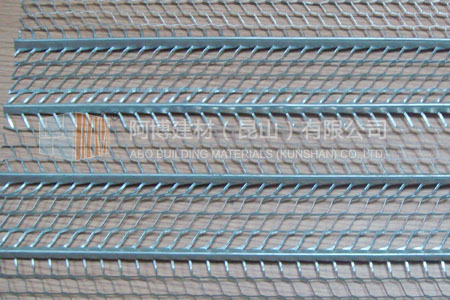

Self-furred rib lath(without paper)

Expanded rib lath

Ribbed lath

Description

Rib lath is expanded metal-lath stiffened with longitudinal ribs. A more rigid lath that the diamond mesh, Flat Rib lath with its 1/8” longitudinal ribs at 3” on center, provide for greater stiffness allowing wider spacing between wooden or metal supports. The furring design of the mesh provides efficient background plaster for construction of partition, suspended ceilings and refurbishment works. The advantage of ribbed- lath over metal-lathing is that support centers can be increased or widened. Flat Rib Lath is available in paper-backed in either K (Kraft) paper, or with D paper. Sizes and specifications can be customized.

Matertal:

0.3-0.7mm Stainless steel or 0.3-0.7mm galv. steel

Specification

Model |

Rib height |

Rib distance (mm) |

Width

(mm) |

Aperture size (mm) |

Remark |

AB-1/8-4-75-450 |

1/8" |

75 |

450 |

9*17 |

9-rib & 4-aperture |

AB-3/8-4-75-450 |

3/8" |

450 |

|||

AB-1/8-4-75-600 |

1/8" |

600 |

|||

AB-3/8-4-75-600 |

3/8" |

600 |

|||

AB-1/8-4-75-750 |

1/8" |

750 |

|||

AB-3/8-4-75-750 |

3/8" |

750 |

|||

AB-1/8-8-100-600 |

1/8" |

100 |

600 |

7*11 |

7-rib & 8-Aperture |

AB-3/8-8-100-600 |

3/8" |

||||

AB-3/4-8-100-600 |

3/4" |

||||

AB-5/8-8-100-600 |

5/8" |

||||

AB-7/8-8-100-600 |

7/8" |

||||

AB-1/8-4-100-600 |

1/8" |

9*20 |

7-rib & 4-aperture |

||

AB-3/8-4-100-600 |

3/8" |

||||

AB-3/4-4-100-600 |

3/4" |

||||

AB-5/8-4-100-600 |

5/8" |

||||

AB-7/8-4-100-600 |

7/8" |

||||

AB-1/8-8-150-600 |

1/8" |

150 |

600 |

11*17 |

5-rib & 8-aperture |

AB-1/4-8-150-600 |

1/4" |

||||

AB-3/4-8-100-700 |

3/4" |

100 |

700 |

7.2*9.5 |

5.66kg |

AB-7/8-8-100-700 |

7/8" |

100 |

700 |

7.2*9.5 |

6kg |

AB-3/8-8-98-686 |

3/8" |

98 |

686 |

7.2*9.5 |

3.34kg |

AB-3/4-8-98-686 |

3/4" |

98 |

686 |

7.2*9.5 |

5.4kg |

AB-3/8-10-98-686 |

3/8” |

98 |

686 |

7.2*8.2 |

3.2kg |

Application

Rib lath is idea for refurbishing damaged or aged masonry walls, when a key for rendering is not certain due to disintegration or softening of the wall face. Lath should be fixed with apexes of ribs against the wall, edge ribs of sheets nesting into each other should be wire-tied every 15cm and ends of sheets should be lapped not less than 2.5cm and nesting ribs securely tied together. Stainless steel fixing should be used at sufficient intervals to hold the lath firmly in position.Competitive advantages

Good and high quality control , prompt delivery , new product , competitive prices , earth-friendly products