What is 3D wire panel?

The 3D wire panel is a unique and effective way to easily create a strong insulated concrete building or wall. 3D wire panels are used in every type of concrete structure because of the flexibility of design and ease of use. Thousands of structure and walls have been built around the world with 3D wire panels. Many of them use the panel for all elements of the structure including walls, floors, stairs and trim. 3D wire panel is used for affordable housing all the way to multi-million dollar housing. Residential, commercial, institutional multi-story all can be created easily with this remarkable code-approved method.

The strength of the 3D system is enormous and is partially attributed to the truss wires which are welded to connect each side of mesh to make the panel. The insulation in the center of the panel is suspended on the truss wires and becomes a continuous thermal break when panels are connected. The performance of the insulation thus is greater than the R-value rating because of the thermal-mass effect of the concrete on each side of the panel.

The monolithic structure with 3D wire panel enables it to withstand earthquakes, hurricanes and typhoons. Many 3D buildings have endured hurricanes with no water penetration or damage, earthquakes with no cracking, and at the same time provided a comfortable and energy-efficient environment for the residents. In the U. S. today there is a strong movement towards concrete housing. The 3D wire panel System is perfect for this market. It provides hard walls and perfectly placed insulation for maximum efficiency. Stay-in-place forms today use polystyrene as molds for concrete and end up with soft exteriors and exteriors which have to be hardened. In the process, they lose the thermal mass effect necessary for energy efficiency. Unlike concrete block, the 3D wire panel provides the insulation and reinforcement strength to concrete which makes it acceptable for residential or commercial construction.

|

|

3D Panel |

3D Wire Panel |

1.Structural Integrity:Concrete and steel are materials for strength and resistance to the elements. Enhanced by exterior infill walls made with 3D wire panel there are no joints to crack and no weak spots that eventually become vulnerable to water intrusion.

2.Thermal and Sound Insulation:Heat and cold transmission is reduced by 50% through the use of 3D wire panel

3.Time and Labor Savings:3D wire panel goes up so quickly, precisely and easily that fewer framers, masons, insulators, and drywall specialists are needed to get the job done fast and right.

4.Environmentally Intelligent:3D wire panel is made from galvanized steel, so the system does not deplete forestry products.

5.Maintenance Savings:Concrete structures require minimal long-term maintenance, especially in areas prone to extreme weather and temperature conditions. Summer heat, winter snow, heavy rains, high winds, nothing gets through 3D wire panel.

6.Lower Utility Bills:Structures built with 3D wire panel have experienced up to 50% savings in electricity consumption, made possible by the use of smaller and more efficient heating and air conditioning systems.

7.Termite Proof:Never worry about this threat to conventionally built apartments and condominiums.

8.Hurricane and Earthquake Protection:There are many documented instances where structures built with 3D wire panel have survived the severest storms and other natural disasters.

3D Wire Panel Application:

Hotel |

Vilia |

House |

Hospital |

Motel |

Officetel |

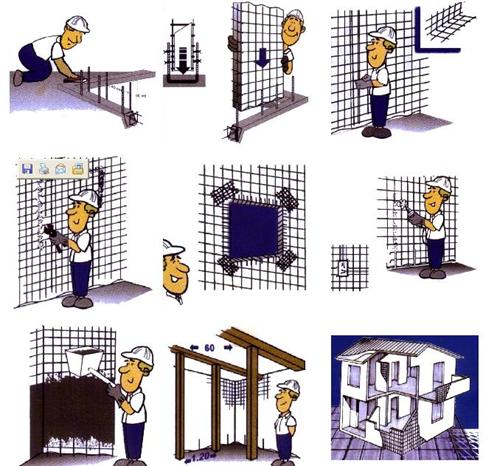

Construction process of 3-D Panel: